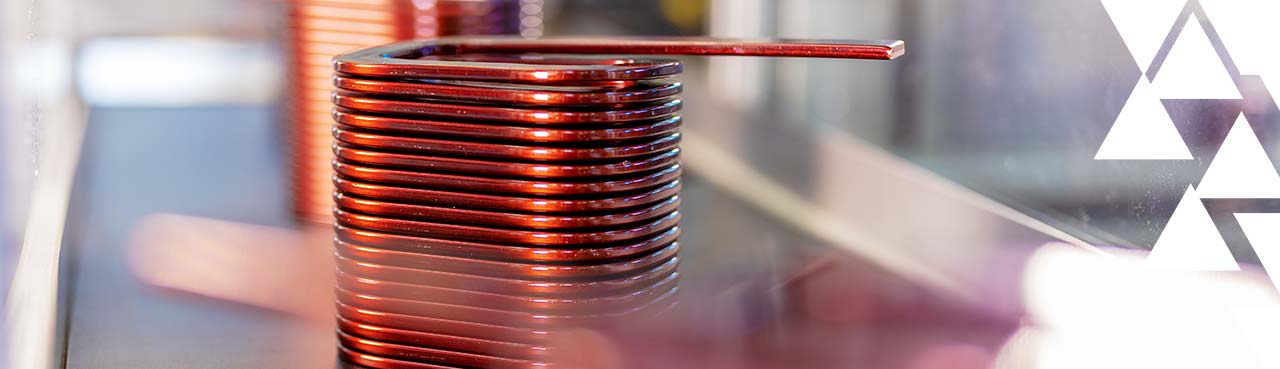

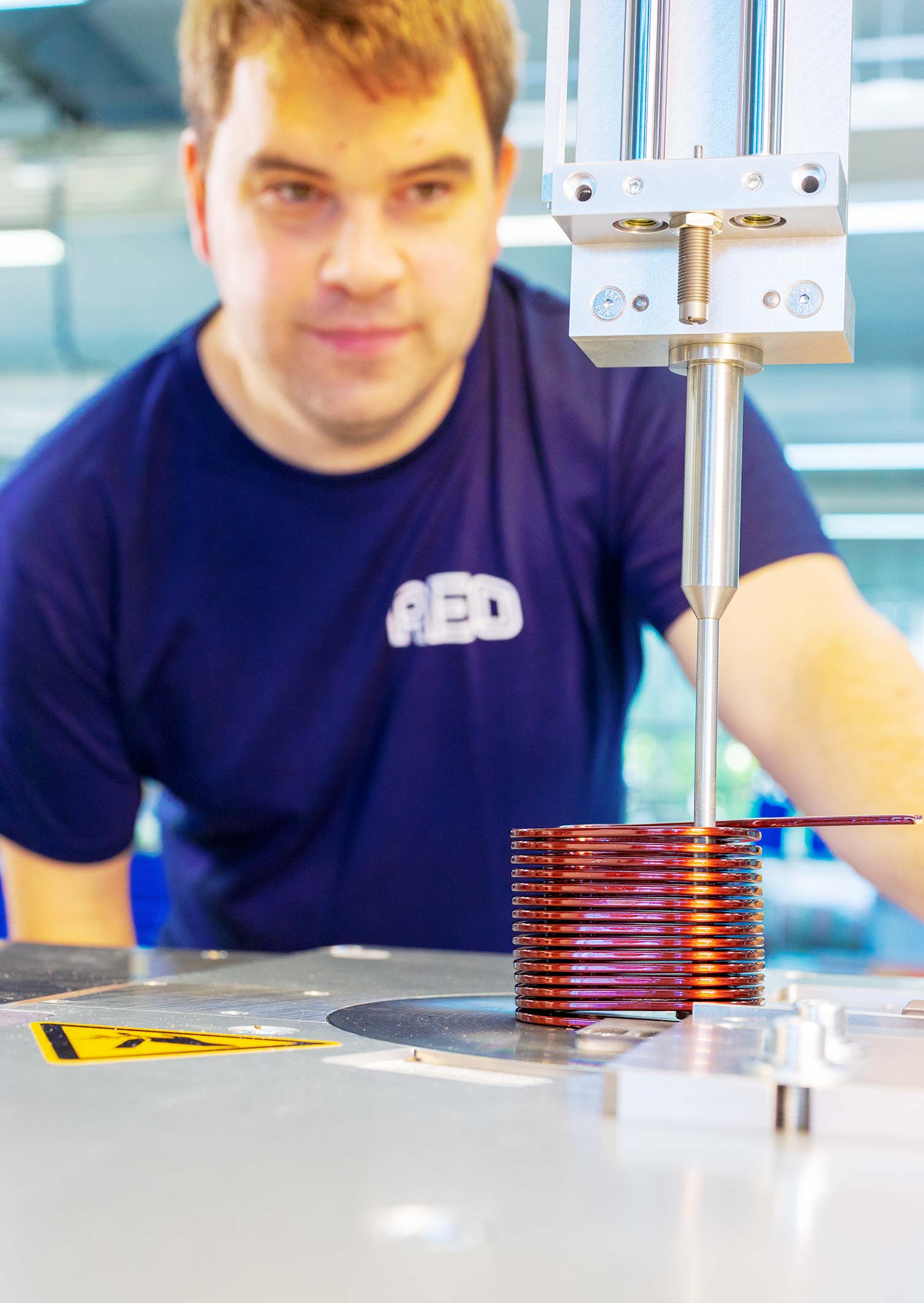

EDGE-WINDING

A development of the REO innovation department

-25% power dissipation thanks to REO EDGE-WINDING

With the introduction of the latest generation of the N CNW choke and filter series, REO is pushing ahead with the use of EDGE winding technology. With increased effectiveness and at the same time lower weight, the new series with high edge winding feature extremely efficient cooling due to their single-layer design – especially with forced cooling. Due to the improved cooling, aluminum conductors can be used as a substitute for copper conductors, depending on the design. In conjunction with automated production, manufacturing costs could therefore be further reduced. The lower weight and smaller dimensions are possible thanks to the reduction of skin and proximity losses. EDGE winding is particularly suitable for semiconductors based on new materials such as silicon carbide (SiC) and gallium nitride (GaN). Due to the lower winding capacitance, the high cantilever winding can also be used at higher frequencies. Almost no insulating material is required, so the service life is increased. The edge winding technology is an innovation of our development team, which is constantly working intensively on the latest technologies and is always thinking along new lines. We have recognized the opportunity of the new winding technology and since 2020 we can produce in small or large series and offer you extremely fast delivery times.

TECHNOLOGY AND INNOVATION

Protection classes and casting

Simulations

Analysis and test methods

Edge Winding

REOFLEX Multiuse-Frame

Liquid cooling

Heavy Duty Catalog

Particularly resilient REO components at a glance

With the new Heavy-Duty catalog, you have for the first time all REO components that meet the highest requirements, clearly arranged and modern at a glance. These include chokes, transformers, resistors, current transformers and complete solutions. In the case of complete solutions, the main focus is on the highly compatible support frame system, the REOFLEX Multiuse Frame. Thanks to the standardized support frame, rail components from REO can be mounted easily, quickly and very variably. For safe damping and suspension, vibration dampers can even be integrated into the unit as required.

Individual development

Customized product development

Individual product development at REO means achieving and maintaining parameters tailored to the customer’s needs, which would not be possible with standard products. Both the electrical parameters and the mechanical, constructive conditions are adapted. Thus, the customer receives exactly the product he needs for his application.

REO is not only a mass producer, but is particularly at home in the development and production of special niche solutions. In close cooperation with our customers, we develop ideas and technical solutions in small or large quantities, which, through their use in an overall system, take over tasks that are not covered by standard products on the market. In this way, we enable our customers to use state-of-the-art applications and innovative production processes without having to resort to standard products with limitations.